We’re reliant on our digital tools. They help us communicate, collaborate and improve the customer experience. And although these digital tools boost our business, they don’t work for every application. Elevating your brand, differentiating your products, streamlining processes, complying with protocols and performing basic business functions can’t be accomplished through digital tools alone. In fact, physical materials, like a well designed custom label, drive additional value, allowing you to:

- Amplify your brand

- Tell your story at the point of purchase

- Improve internal processes

- Adhere to protocols

- Deliver personalized information

- And more

Use this guide to create effective custom labels that elevate your marketing, improve your operation and complement your strategies in ways that aren’t possible with digital alternatives.

Guide To Creating Effective Custom Labels

Guide To Creating Effective Custom Labels

As Clayton Christiansen stated in his book Competing Against Luck, when we buy a product, we essentially “hire” something to get a job done. For example, when installing the hardware on a new kitchen cabinet, “People don’t want to buy a quarter-inch drill. They want a quarter-inch hole.”

Similarly, when it comes to custom labels, you don’t want a label, you need a vehicle that:

- Sells a product

- Promotes your brand

- Conveys personalized information

- Improves medication safety

- Enhances protocols

- Improves operational processes

- Tracks inventory

- Identifies parts

- Labels shelves

- And more

Identifying this “job to be done” is the first step.

Because it drives the custom label design, colors, shape, size, materials and more, let’s examine the features that are important for each of these functions.

Product Labels

Product Labels

How often does the label on a craft beer or bottle of wine cause you to pick it off the shelf, examine it further and ultimately buy it? In fact, a custom label is the first thing customers see and when designed effectively, it grabs a customers’ attention and triggers a purchase.

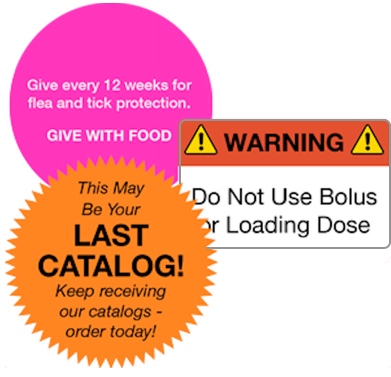

In addition, products often contain secondary labels that further promote the product, provide instructions, health information and more. For a product label to attract the consumer, it typically incorporates a variety of elements including:

- A high color design

- Unique shapes

- Durable materials

- Attractive finishes

Brand Labels

Brand Labels

Often used to complement information already on a product or package, a brand label highlights your company and important information about it. A well designed brand label can create a positive impression and convey other important details including:

- Contact information

- Hours

- Follow up appointment times

- Special offers

- Your mission

- And more

Similar to product labels, a brand label normally incorporates

- A high color design

- Unique shapes

- Attractive finishes

In addition, when exposed to running water, moisture and steam, frequent handling and more, a durable finish is also a necessity.

Personalization

Personalization

Making communications and product experiences feel unique to a customer is the power of personalization. When you target your communications to a specific company or person, it is more likely to capture and keep your audience’s attention and provide a greater return on your investment. For example, a personalized label applied to an envelope or package has a greater impact on the consumer and enhances your brand.

But for custom labels, personalization extends beyond this definition. For example, many companies, including UAL, provide stock labels that serve various functions. But, there are situations when the stock format doesn’t meet the individual requirements of the operation, such as the following:

- Service labels that note completion dates and quantify the type of service performed may also need the standard contact and emergency information of the service company

- To meet internal protocols, medication labels may require specific colors different than the ASTM standards

- Prescription bottle labels that guide proper medication dispensing

- Product labels that need an expiration date, lot number or another unique numbering or barcode series

- Adding how to instructions or safety information to a product

- Signage that guides consumers or encourages them to take action

- Message labels that offer a personal touch or provides your audience helpful information

- Shipping labels with a logo and other appropriate branding elements

- Shelf labels with unique barcodes, numbering or other identifiers

The design, color requirements, shape, size and materials of a personalized label vary because it typically needs to follow the specifications of the item it parallels.

Once you define your custom label’s “job to be done,” designing the label is the next step.

Designing The Label

As outlined above, the purpose of your label drives the features you need to incorporate in the design. Those include:

- Label Materials

- Label Color

- Label Shape

- Label Size

- Label Finish

- Application Method

Let’s walk through each one.

Label Materials

Label Materials

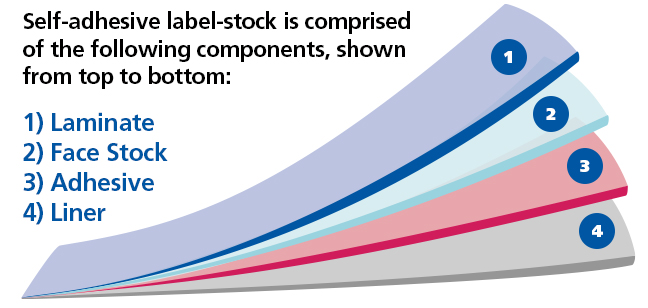

A custom label is produced using four distinct parts:

- Laminate

- Face Stock or Material

- Adhesive

- Liner

Each one plays an important role in designing a label that best fits your application.

Laminate

Applied over the face stock, a laminate serves as a protective shield, increasing the durability of the label. Plus, it can serve as a design element, enhancing colors and creating a dimensional effect.

Face Stock

The face stock is the top layer of the label. It the layer that holds the ink on one side and the adhesive on the other. Common face stocks come in two basic categories, paper and synthetic. Other options such as vinyl, foil and even dissolvable materials are less common but appropriate for more unique applications.

Label Adhesive

The adhesive serves as the glue that adheres the label to a substrate. Many different types of adhesives are available including permanent, removable, repositionable, high heat and cold temperature.

Label Liner

The label liner is the bottom layer of the label and is the material the label and adhesive rest on. Although the liner is discarded after use, it plays an important role. For example, during the manufacturing process it allows a die to cut through and shape the facestock while the liner remains intact. Then it acts as a conduit during the finishing process so the labels can be wound as rolls, sheeted or slit in a crack n peel format. Lastly, the liner contains a silicone coating which allows the facestock to be removed from the liner so you can easily apply it to the substrate.

When selecting the best face stock and adhesive for a custom label, the end use of the item it’s applied to and the conditions that item is subjected to are important data points. If you don’t account for application, handling and use, the label may fail.

Label Color

Label Color

From single to multi colors and four color process, the label color reflects your specific design requirements. For a general purpose custom label, one color is often sufficient. But, when the design and branding are essential, like a product label, multiple colors are often the answer. United Ad Label employs a variety of printing processes that allow you to achieve your design and color objective in the most economical way.

Label Shape

The label manufacturing process makes it possible to construct almost any shape. And although a unique shape integrated into the design may make sense for a customer facing brand, there’s good reason to use more conventional shapes when possible.

For example, squares, rectangles, circles and starbursts are standard shapes readily available at most label manufacturing companies. Using these shape options typically result in both faster production times and lower prices. In addition, if you are adding variable information to your label using a desktop printer, the shape you choose has to accommodate that printed information, so design accordingly.

Yet there are reasons why a unique shape makes sense. For customer facing items, the shape is often integrated into the label design. Plus the shape of the product the label is ultimately applied to can also drive your selection. But one downside to a unique shape is the cost. Because forming that unique shape will likely require a custom die, the overall cost of the label may increase.

Label Size

Similar to the shape, in theory there are an endless amount of potential label sizes to choose from. Although factors including the type of product you are labeling, the amount of space available on the substrate, where the label is applied and more, may dictate the actual size you need, using standard sizes that accommodate both basic and unique custom applications can save you time and money.

Label Finish

The label finish provides a number of benefits including protecting the label against moisture and chemicals, increasing it’s durability, enhancing the design and more. There are a variety of label finish options to choose from.

Varnish

Varnish is a label design treatment that can help make colors and information stand out. Plus, similar to lamination, it can serve as a way to protect the ink and label material but is a lower cost option than a laminate. Like paint, varnish comes in both gloss and matte finishes.

In addition, other varnish options include:

- Imprintable - for applications that require imprinting additional information such as an expiration date or lot code. This varnish also accommodates handwriting with pens and markers without smearing.

- Spot - allows you to highlight specific areas of the label making it stand out. It’s commonly used to add depth to design elements including a logo or an image.

- Soft touch - provides a plush type texture making the label feel better to the touch. It also creates a fingerprint resistant barrier.

Application Method

Application Method

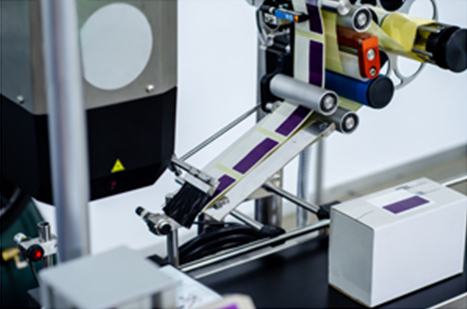

From applying a label to the substrate manually to using automated equipment to perform the task, the application method is an important step in label design process. For a general purpose, medication, IV label or others that are hand applied, either a roll or sheets work effectively. But when using automated equipment, the core size, outside diameter, unwind direction, liner and more influence the design and ultimately the manufacturing process.

Pricing The Label

Which of the above design elements do you need for your custom label? To determine the price, a label manufacturer needs to know which specific elements you need and the total quantity of labels you plan to purchase.

There are also online custom ordering tools you can use. For example, the United Ad Label Custom Label Designer allows you to design, price, proof and order custom labels. Plus, this tool also allows you to change inputs to determine how different features impact the price.

You can learn more or try it for yourself here.

Once you’ve defined the specifications and quantified a price, printing your label is next. Consider these attributes when selecting a custom label manufacturer:

- Multiple print technologies - choosing a company that employs various print technologies will allow you to leverage the option that best fits your application and keeps pricing in check

- Supply chain - a company with a strong supply chain has better access to materials which translates into better delivery times and pricing. Learn more about how UALs works with their supply chain to minimize costs and avoid shipping delays here.

- Experience - understanding the nuances of your application leads to better outcomes

United Ad Label

United Ad Label brings over 60 years of experience, strong supplier relationships and an unmatched array of print technologies that allow us to deliver economical, high quality custom labels in quantities large and small. If you have questions or need to place an order, you can speak directly with our customer service team or use our Custom Label Designer app.