Barcoding 101

Types of Barcodes

1D Barcode - The traditional barcode people are used to seeing, such as UPCs, are considered to be 1-dimensional or linear, as they will represent data in a linear fashion. Some examples of 1-dimensional barcodes:

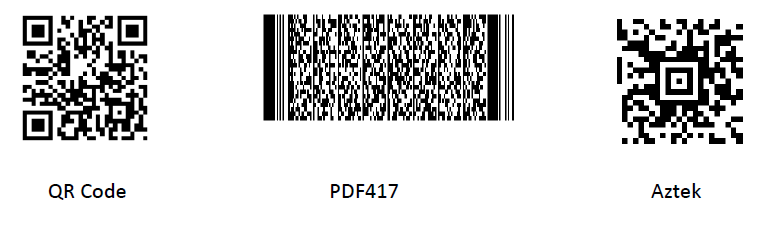

2D Barcode - A 2D bar code or matrix barcode can be used to encode data such as a serial number or item number and lot details for tracking. It takes up less space, can be read in any direction and its popularity is growing. A few of the more popular 2D barcodes:

Which Barcode is Best?

This depends on your needs and your hardware. Laser scanners, the cheapest type of scanner, only read 1D and PDF417, so if you have a laser scanner you will need to use a linear barcode. The compact size and the ability to encode multiple fields into a single bar code are great benefits of 2D technology. If the user has to scan from different angles, has a very small area to encode a lot of information, then a 2D barcode is a great option.

One thing to note: if you want to use a 2D barcode, an “imager” scanner is required to scan it. A traditional “linear” scanner cannot read a 2D barcode. Also be careful when combining multiple barcodes close to each other, such as on a wristband or a circuit board. You may have scanning issues because the imaging scanner captures the entire image of the article to be defined and there is less accuracy than aligning the single red laser on the intended bar code.

1D Barcode Advantages

- Easier to scan since information is vertically redundant. A “slice” of readable bars and spaces anywhere up or down the barcode is all that is needed.

- No distortion on the curved side of a tube

- More compatible with older handheld scanners

1D Barcode Disadvantages

- The main disadvantage of linear barcodes is size. Since only single dimension is used to encode data, 1D barcodes tend to be longer.

- Not suited for very small areas due to size of barcode

- No available rack scanners

2D Barcode Advantages

- High-density encoding of information creates a smaller barcode

- Well-suited for small labels

- Error correction allows for reading of damaged codes

2D Barcode Disadvantages

- More difficult to scan, especially if multiple barcodes are involved

- Not well-suited for curved surfaces due to distortion or “bowtie” effect

- Fewer compatible scanners. Legacy scanners are likely unable to read.

Bottom line: When adding bar code technology, identify if 2D barcode data capture may be required at some point. This will help you determine your hardware investment.

Colors for Labels and Barcodes

Take care when choosing label colors. There must be ample contrast between the colors of bars and spaces between the bars (white area) for the code to be read properly. For the best possible scan, bars should be black or a very dark color and spaces between and around bars should be white or a light color that will contract with black. Besides black, dark green, blue and dark brown are good bar colors. Besides white, red, yellow and orange are good space colors.