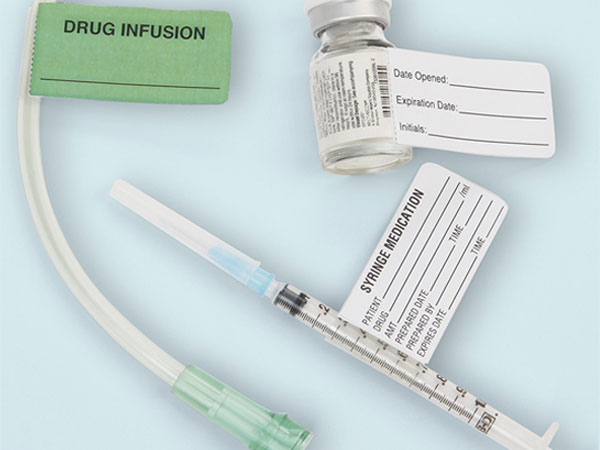

Medical Flag Labels

When does a simple medication flag label complicate procedures for medical professionals? When the design fails to accommodate the needs of users. Learn how a major Health System significantly improved the medication handling process, enhancing patient safety and reducing costs.

Executive Summary

A large health system with 50 hospitals and over 800 clinics provides hundreds of programs and services for patients in the northwestern United States. They are known for high-quality, compassionate health care. But maintaining those high standards isn’t easy. Ongoing evaluation of current processes is a must. And one process they were constantly seeking to improve was safety. So, they turned to RRD for a solution that:

- Worked seamlessly with their current systems including Epic and Pyxis and Omnicell stations

- Allowed for barcode application and scanning on small syringes and vials

- Eased caregiver handling challenges and improved patient safety

- Reduced SKUs

- Controlled costs

Medication Dispensing Safety And Security Challenges

Medication dispensing is crucial in any hospital. But, the importance of an effective process increases with a staff of more than 50,000 doctors and nurses. Although their current procedures were meeting current protocols, they did experience challenges. For example, the health system was installing EPIC but used Cerner in the Pharmacy. The medication labeling solution needed to incorporate formats and procedures and work effectively with both EHRs. In addition, they used various types of flag labels and experienced a number of issues including:

- Vial labels shifted during refrigeration which sometimes made it difficult for the medical team to see dosage levels

- They used a laser printer which printed one sheet at a time. Each sheet contained eight labels but they rarely needed all eight which resulted in significant waste

- Blockout labels provided the necessary HIPAA and Joint Commission patient security safeguards but the costs were excessive

Understanding The Current Process

With their knowledge of hospital department processes, software systems and label materials, the Health System partnered with RRD to analyze the current process and recommend improvements. Working with the Pharmacy and nursing staff, RRD reviewed the flag labels used throughout the system. For example RRD:

- Recorded the specifications for each unique label including size, colors, copy, materials and adhesives

- Worked with the pharmacy to understand how the labels were printed when orders were received

- Worked with the medical staff to determine how the labels were applied and used in medical situations

This in depth analysis allowed them to recommend a course of action.

Process Improvements

The material analysis and discussion with staff revealed a number of issues:

- Some labels contained a removable adhesive not made for cold applications. This caused the vial labels to do one of two things; shift on the vial or permanently adhere to it during refrigerator storage.

- The nursing staff used separate medication and flag labels. This created an extra SKU the Health System had to manage. In addition, the two labels with similar functions caused confusion in some departments

- Printing labels in multiple locations in the pharmacy, resulted in a slower process.

As a result of their findings, RRD worked with the health system to implement an improved Flag Label process:

Reduced four unique labels into just one but maintained the four separate functions required.

- IV and syringe labels were combined into one single label, plus the design now allows use as a drug syringe flag

- The new design included a perforation that functions in two ways, for multi dose medications and as a receipt that can be attached to the patient’s medical record.

- Only the clear adhesive portion of the label is applied until released from the pharmacy. Reducing wasted labels covering up critical information on vials, IV Bags or medication packaging.

- Ability to use the same printer footprint already in the pharmacy and remove all unnecessary printers to free up bench space.

- The new design works effectively in the EPIC and Cerner environments

Summary

RRD developed and implemented a Flag Label system which combined unique functions together into a single process. The new process made it simpler for the pharmacy and nursing staff. In addition, the new label materials eliminated labels shifting or adhering permanently to vials improving patient safety. Lastly, the new process allowed printing on thermal printers. This completely eliminated the labels wasted on laser sheets. RRD provided a cost effective solution that reduced unit costs and improved productivity.

United Ad Label stock and custom flag label solutions improve the medication handling process, enhancing patient safety and reducing costs.