Healthcare

Central Sterile & Sterile Processing Department Labels

What Are Central Sterile Labels?

Central sterile labels communicate the clean and sterile status of healthcare equipment and trays. Health systems and hospitals use central sterile labels to elevate patient safety, improve efficiency and maintain regulatory compliance.

Common Central Sterile Label Uses In Healthcare

Central sterile labels identify the sterile status of equipment, trays and central supplies, improving the management of equipment returns, reagents, central supply bins and more. Plus, they detail sterilization and expiration dates on medical devices and code and date patient care products.

Central Sterile Labels At United Ad Label

United Ad Label provides central sterile labels in a variety of colors and shapes that ensure information is communicated effectively. Our labels contain special autoclavable adhesives that guarantee adhesion during the sterilization process and withstand autoclave temperatures up to 302?.

Types of Central Sterile & Sterile Processing Department Labels

View All

Autoclavable Identification Tapes

Autoclavable identification tapes identify items such as surgical instruments and distinguish cleaning protocols.

Clean Communication Labels

Clean communication labels show that instruments are ready and safe for your patients.

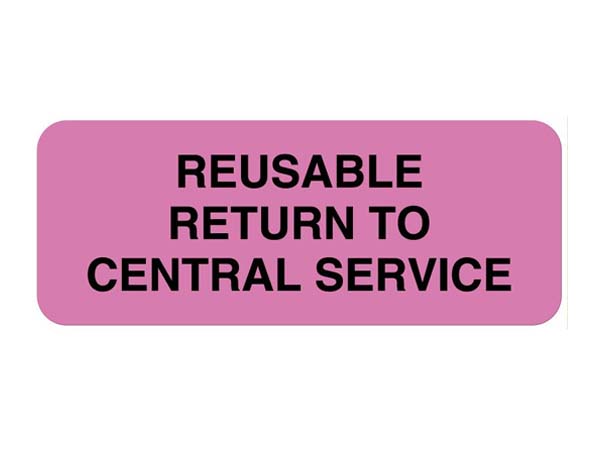

Equipment Return Labels

Equipment return labels instruct employees on how to manage Central Service supplies.

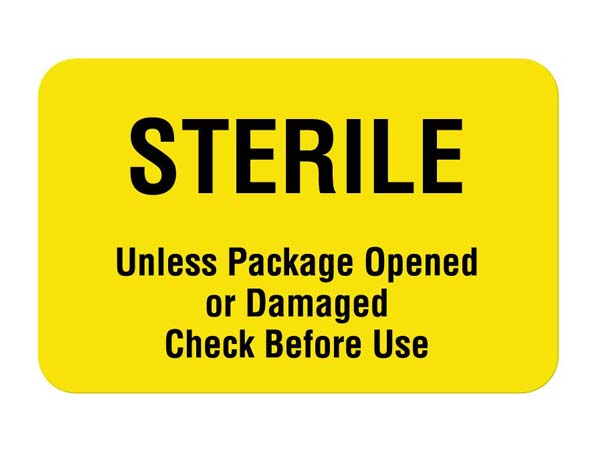

Event-Related Sterility Labels

Event-related sterility labels show sterility expiration dates clearly and quickly.

SPD Shelf Marking Labels & Guns

SPD shelf marking labels and guns provide you with a greater flexibility in coding and dating your patient care products.

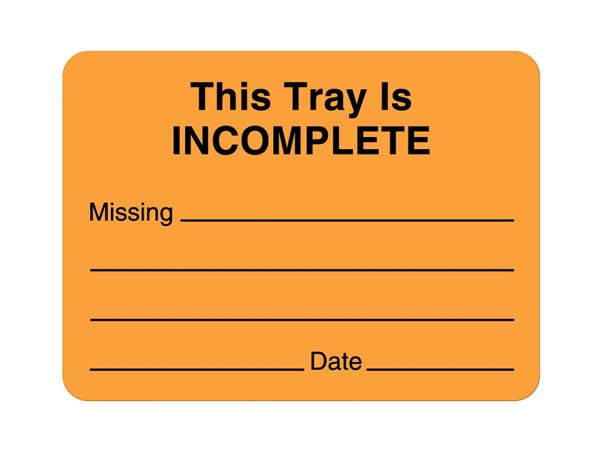

Tray And Cart Labels

Tray and cart labels help track instrument counts in trays.